Deep-learning

New Self-learning tools in the field of computer vision allow manufacturers to implement computer vision systems with a short investment return. With our new technology, our system ‘learns’ to distinguish between ‘functional’ and ‘defective’ products without the need for special software.

COGNEX ViDi – Deep-learning based on industrial photo analysis

VIDI of COGNEX is proud to present the first deep-learning tool in the world that can be used for computer vision systems and analyze industrial images. The tool was developed in its present form to enable fast, easy implementation, with a simple, convenient interface for the automation systems on the manufacturing lines.

VIDI is a product that has passed rigorous tests. It is based on algorithms developed by a group of scientists from Switzerland.

The VIDI tool enables coping with existing challenges in the vision world. Applications that were impossible to import until not long ago due to non-unified background, multipolarity of products, inability to define a defect in physical terms, inability to separate elements, and more…can now be achieved thanks to VIDI.

VIDI is comprised of three software elements:

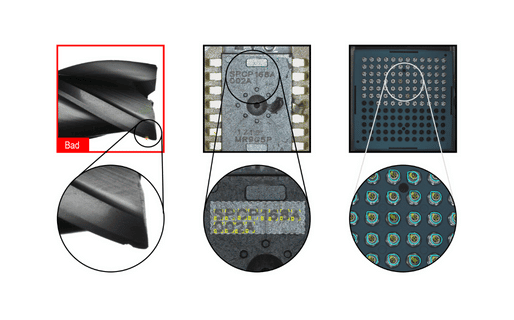

The ‘blue’ tool of VIDI is the location and identification tool. It serves for locating single or multiple elements in an image.

These can be characters from a defective printed document or poor sealing on a non-even surface with a noisy background, or a large number of objects in a given area without physical separation. The blue tools can locate and identify the objects by studying marked reference photos. All that is needed to train the blue tool is reference images where the elements required for location and identification are marked.

The ‘red’ tool finds defects and sorts them into categories. With this tool, you can detect anomalies and aesthetic defects in the tested product. These can be scratches on an ornamented surface with changing backgrounds, non-full, or non-proper mechanisms, or even weaving defects in the textile.

Training the red tool is done by studying the regular appearance of the object, including its unique elements.

The ‘green’ tool defines and classifies the tested object. Classification can be carried out by testing the products according to their packaging, welding method or quantity and number of defects.

The green tool can carry out these classification activities by learning the reference image of the various products. All the user has to do is load onto the system several groups of images separated by the definitions of the required test.