Drives and Motors

Rockwell Automation – servo motors

Contel is the formal representative of the servo motors, the linear motors and electrical pistons of Rockwell Automation (Allen-Bradley).

Contel provides mechanical planning services, drive application planning and installation at the client’s site.

We have a team of professional engineers responsible for the mechanical planning, implementation and integration.

Contel provides high- level solutions for the drive systems of Rockwell Automation (Allen-Bradley).

Movement control technologies with high level performance

A wide variety of features and available technologies in the speed regulators and drivers of Kinetix that allow the client to make the perfect choice for his machine.

The linear, LCD servo motors provide linear location control at high speeds. Linear motors with direct drivers are directly connected to the load that is to be driven. The direct driver allows the servo motor to react quickly, resulting in shorter movement stabilization times. The LDS series is planned with an iron core of high power density.

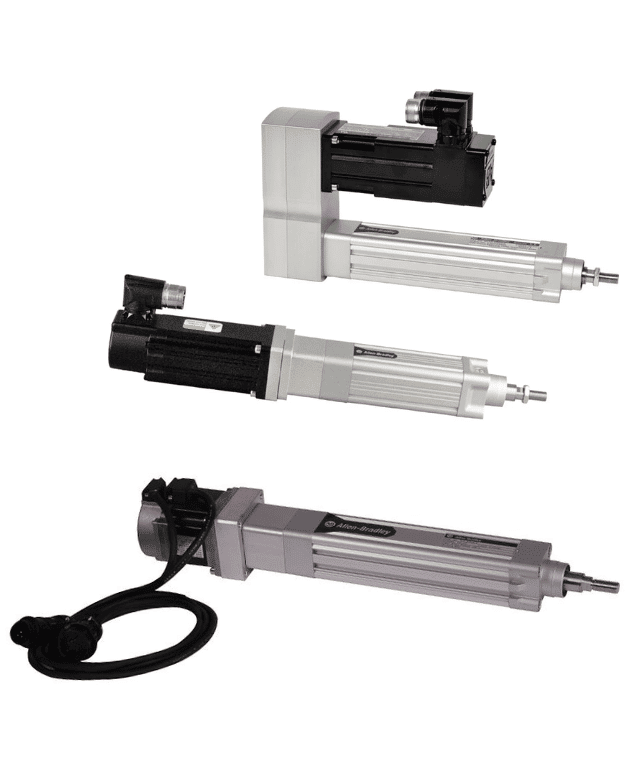

The electrical pistons series of models MPAR MP and TLAR TL provide dynamic, accurate reactions to a wide variety of linear movement applications.

These pistons can be programed via the RSLogix™ 5000 software (version 20 or older), to achieve great accuracy in location, speed, and force.

The end- devices for these pistons are standard, thereby simplifying the assembly process, and shortening the mechanical planning time, wiring and delivery.

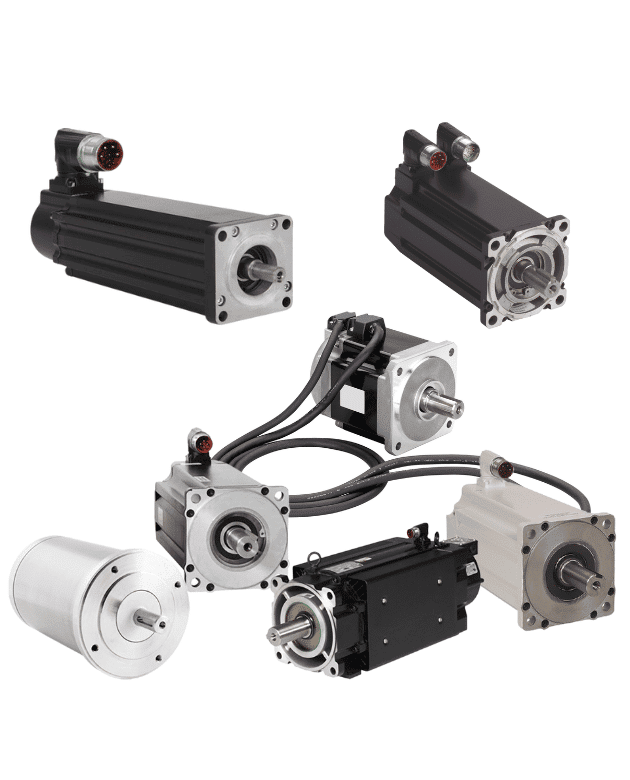

Servo motor – Allen Bradley

A rotational servo motor that meets the strict requirements for linear drive systems. The motor is connected to the 5500 Kinetix disk driver via one cable to receive feedback. The MP motors series includes low inertia, moderate inertia and stainless steel motors. The HPK motors series offers quick acceleration and deceleration. The TL motors series offers compact motors with low inertia. There are server motors suitable for the food and medicine industry and for clean rooms

With a team of engineers responsible for mechanical planning, software writing and integration, Contel provides high-end drive solutions that use JVL and Allen Bradley products.

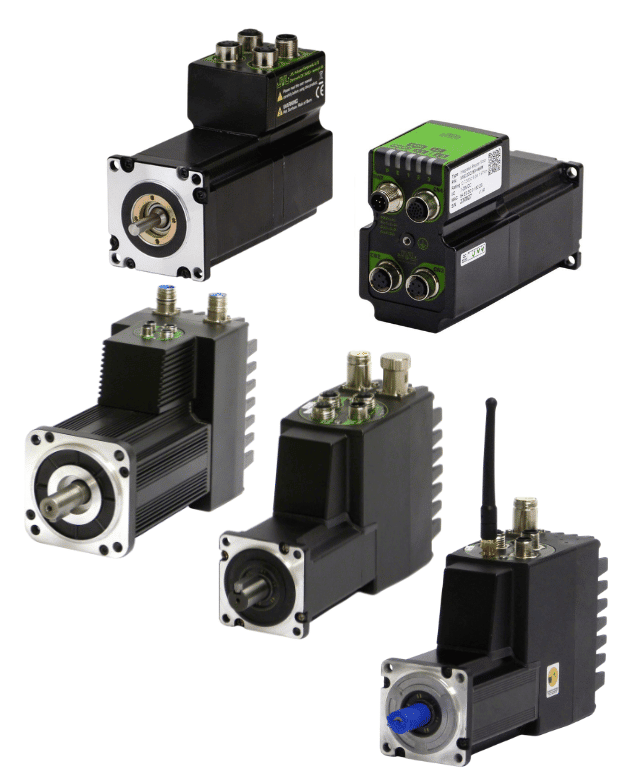

Servo and JVL stepper motors

Servomotors are hybrid and integral motors with a full drive solution, a controller and an absolute encoder in one unit. These motors are compact, since they eliminate the need for a driver and for heat removal from the cabinet.

- JVL motors have an extremely high motor moment of +40%

- Industrial Ethernet

- Industrial communication protocols such as: IP, Profinet, EtherCat, Modbus Ethernet, CANopen and more

- Work in full closed loop

- Built-in safety element – STO

- High resolution cnt/rev 409600

- Double motor axis (front and back)

- RPM 0-3000 speed in a resolution of 0.01 steps

- Electromechanical brake

- Voltage supply VDC7-72

- Insulation level up to IP69K

- M12 industrial metal connectors

MAC – servo motor without brushes, with an integral controller

The basic idea of an MAC motor is to mitigate the installation costs, and protect it against electrical noise, which can become a problem when using long cables between the controller and the motor.

The encoder and the electronics in the Hall Sensor of the servo motor were developed by JVL to create a closed loop where the drive unit and the controller are installed in the motor in a closed part.

You may choose the module that suits your motor- connector type BLUETOOTH D-Sub or M12. Communication protocol: Profibus DeviceNet, CANopen, Ethernet/IP TCP IP MODEBUS or Nano PLC controller. It is possible to add high speed and wireless modules.

This means that the MAC motor provides you with capabilities that no other motor in the market can provide. You pay only for what you need. If you cannot find the features you need, contact us, and we would be happy to create a tailored module for you.

MIS and stepper motors with an integral controller

The basic idea of an MIS motor is to mitigate the installation costs, and protect against electrical noise, which can become a problem when using long cables between the controller and the motor.

The encoder and the electronics in the sensor hall of the stepper motor was developed by JVL to create a closed unit where the drive unit and the controller are installed in the motor in a closed part.

The MIS stepper motors are provided with a variety of connection options to the M12 connector depending on the required application.

For the MIS stepper motors there are built-in RS485 PLC communication protocols and an option for standard industrial communication such as : Profinet, EtherCAT, Ethernet IP, Powerlink or an MODBUS TCP / IP interface

For all MIS stepper motors, there is a magnetic, absolute, built-in encoder. The MIS34 series includes an absolute MultiTurn encoder.

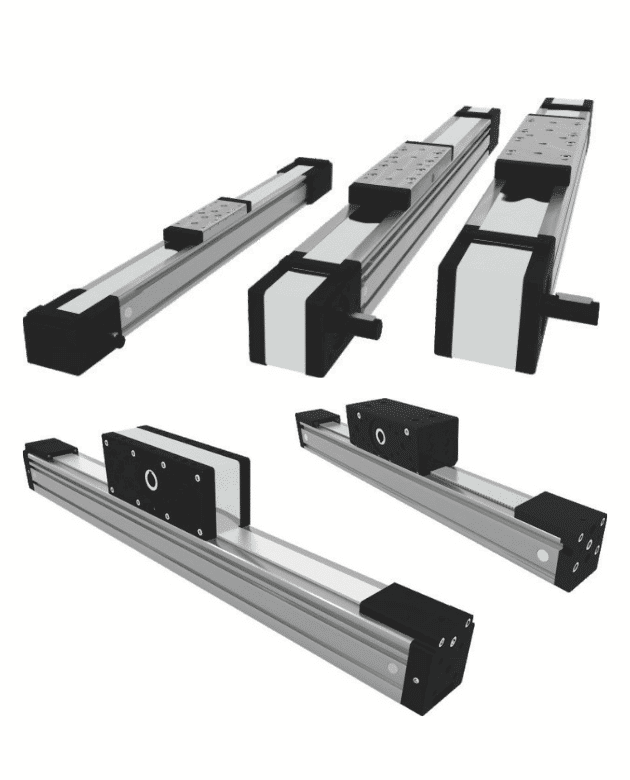

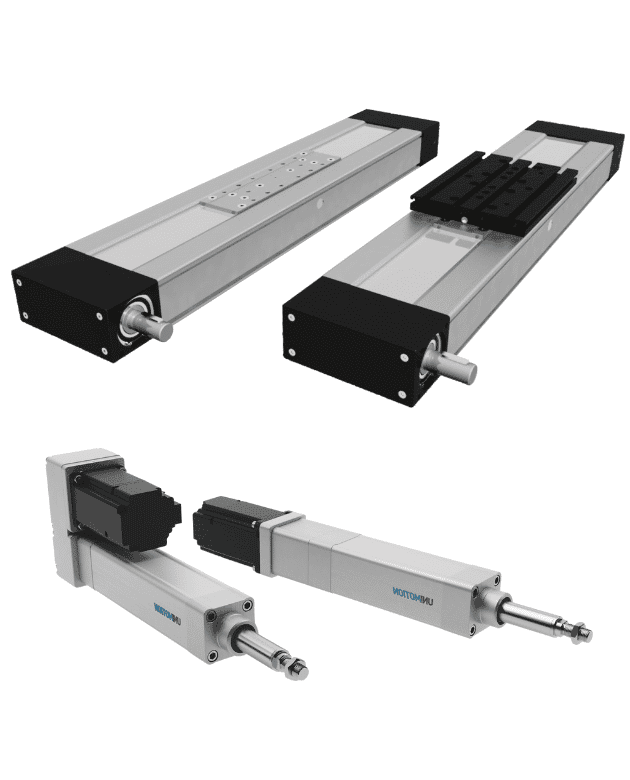

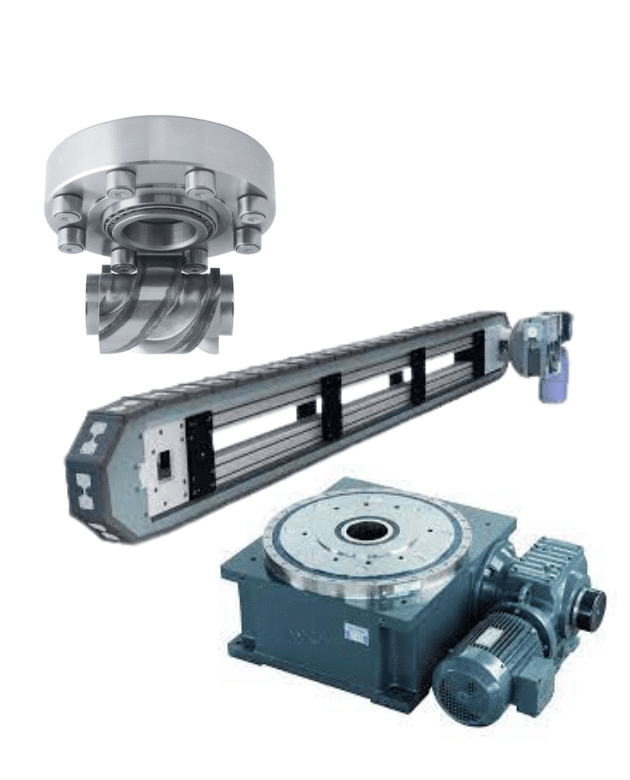

UNIMOTION – linear drive solutions

Contel is the exclusive supplier on behalf of UNIMOTION, a leading manufacturer of a variety of linear mechanical units, compact linear units, electrical cylinders based on the ISO 15552 standard, multi-motor systems and tailored solutions. Contel provides configuration, planning and installation services for drive applications at the client’s site.

With a team of professional engineers responsible for the design of the various applications, mechanical design and engineering, Contel provides high- quality solutions for movement applications based on UNIMOTION products.

UNIMOTION is known for the quality and reliability of its products in terms of great value for money and short delivery times. Therefore, when it comes to the manufacturing of standard and tailored, complex linear units, the company can ensure high production, flexibility and accuracy.

UNIMOTION linear units:

- Units driven by a ball screw

- Units driven by a belt

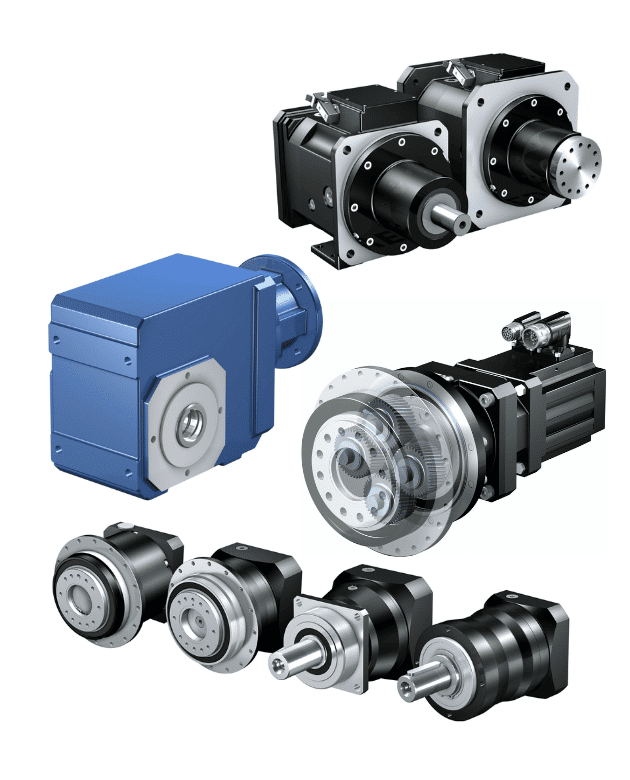

Planetary gear

The planetary gear of STOBER is suitable for all servo motors. The German STOBER company specializes in the planning and manufacturing of a wide variety of planetary gears, with a low backlash as a standard for servo motors. The high density of the gear cogs limits movement range and increases accuracy, thus achieving 97% utilization.

Planetary relay

A planetary relay that combines a built-in pinion relay. In addition, for the first time, the screw brush cover enables full utilization of the conduction moment.

Gear motor

A synchronous gear motor, axes gear motors, and non-synchronous gear motors are economical, since they eliminate the need for an adjustment plate between the motor and the gear. With a team of professional engineers responsible for the mechanical planning, implementation and integration, Contel provides mechanical planning services, drive implementation planning and installation services. Contel provides high level solutions for the drive systems of STOBER.

Itaplant – index tables and accurate belts

The special brush of the MK2 indexers series for high speeds makes this series a leading one in the industry for fast machines. Today, the company offers speed rates of up to 1000 cycles per minute. ITALPLANT develops and manufactures a machine for cutting and engraving brushes and projections for its products. We have been working since 1990 with the leading indexers company CAMCO. Charlie Nims and Larry Gankarz (the company’s president and VP, respectively) opened a joint venture for selling the accurate link belts in Italy. Today, the company’s PLC products are manufactured by extremely accurate machines with a TTC system and a 0.04 mm accuracy for a length of 8 meters.

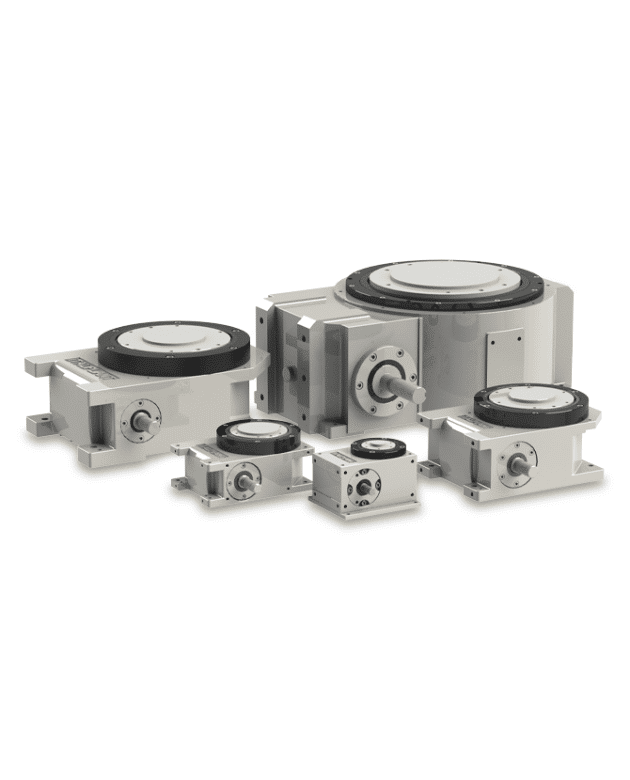

TAKTOMAT- index tables

Contel is the official representative of the index tables and all drive products made by TAKTOMAT. Contel provides mechanical planning services, drive application planning and installation at the client’s site. We have a team of professional engineers responsible for the mechanical planning, implementation and integration. Contel provides high- level solutions for the drive systems of TAKTOMAT. TAKTOMAT specializes in the planning and manufacturing of a wide variety of index tables with fixed and changing distribution.