Infrastructure and energy management

PlantSharp Energy – measurement of energy consumption and billing

PlantSharp Energy – a system that controls, collects, stores, and manages energy consumption data in air-conditioning systems, and splits the costs between different users according to their actual consumption. The system is based on an up-to-date SAAS technology that enables access to, and control of all data from any place in the world and from any computer or smartphone. The energy consumption data and other data can be transferred from the energy and electricity gauges in the tower to the local connector. The local connector transfers the data to a cloud server via an OPC server. Since the system is based on OPC communication, the pace of communication and reading of energy data from all consumers is fast. The data are backed by the cloud. Saving the data on the cloud ensures high reliability. Installation at the user’s site is not required.

The system does not require a special computer. The user can enter the software directly from the browser in any device. The software calculates the KWH or R costs of air-conditioning through routine reading of the electricity and energy meter.

The PlantSharp Energy software enables accurate issuance of consumption bills for tenants and public areas. The system reads the energy, electricity, and water meters via various communication protocols (M-BUS, MODBUS/RTU , BACnet/MSTP). The sampling is carried out every hour or at other intervals defined in the system. The system enables observation and continuous reading of energy production costs according to seasonal and hourly tariffs.

Use of IOT/ IIOT

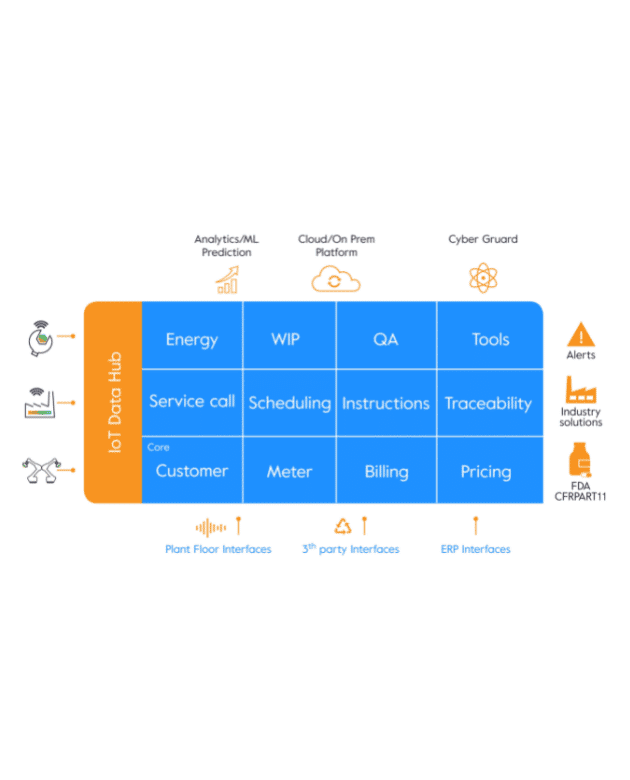

The IIoT (Industrial Internet of Things) improves connectivity between machines, increases manufacturing efficiency, supports gradual and exponential increase in information, and saves time and costs for industrial organizations. All of the above is enabled thanks to predictive maintenance, improved safety, and increased operational efficiency. The IIoT network for smart devices allows industrial organizations to store and analyze information from the manufacturing floor, information which was until recently hidden.

The IIoT allows the managers to use these data to gain a full image of all manufacturing and information layers in the organization, thereby enabling informed decision-making in real time. Support of multiple protocols, information architecture, and information security are the key challenges when it comes to implementing the IIoT. We enable the completion of the tough task of gathering information from various sources (controllers, detectors, sensors, gauges, etc.), some of which are old.